“OSG Corporation gives Somta Tools factory thumbs up with R60 million investment” editorial in Metalworking News July 2019 (solo en inglés)

OSG Corporation, regarded as a global leader in the manufacture of round cutting tools and a company that is listed on the Tokyo stock exchange, has given the thumbs up to its South African manufacturing operation by earmarking a further significant investment in the Somta Tools factory in Pietermaritzburg, KwaZulu-Natal. OSG Corporation acquired a majority shareholding in Somta Tools in 2016 and has already made substantial investments in equipment and processes at the local manufacturing facility.

Somta’s new DMG MORI NLX 1500 universal CNC mill turn machine to prepare a variety of blanks

“OSG Corporation is investing R60 million over the next 24 months in new technology and equipment at its Somta Tools factory in Pietermaritzburg. This is an unprecedented investment in South Africa’s cutting tool industry and will go a long way toward helping Somta to achieve its goal of becoming the undisputed leader of machining solutions in Africa, and aligning itself with Industry 4.0, a global trend allowing a seamless process from raw material to finished product,” said Allan Conolly, Managing Director of Somta Tools.

“This is not the first time that the OSG group has invested in the Somta Tools factory. In 2018 we installed OSG designed and manufactured CNC equipment in both the high-speed steel (HSS) and tungsten carbide factories to improve the finish and geometry on the tools and to reduce setup and cycle times,” added Conolly.

“In addition, new measuring and inspection equipment was introduced to improve the degree and frequency of the stringent quality checks that take place during the manufacturing process. This development improved our in-line inspection capabilities such as measuring key geometries more accurately, resulting in greater consistency, reduced cycle time and improved tool life,” explained Conolly.

Somta have also invested in a Haas VF2 SS CNC milling machine

“The investments in new technology are key to enhancing productivity and quality, the benefits of which are immediately being passed on to our customers through price reductions and improved tool performance.”

2019 investments

“Our investment in equipment this year thus far has seen the introduction of a number of new machines and quality and measurement solutions into Somta’s manufacturing plant.”

“In the blanking preparation department we have installed a new DMG MORI NLX 1500 universal CNC mill turn machine to prepare a variety of blanks. The DMG MORI combines two operations that previously would have needed to be done on two different machines.”

“Additionally in the blanking preparation department we have invested in a Haas VF2 SS CNC milling machine. The Haas has been equipped with a trunnion table that will allow us to do 5-axis milling. This means it can combine up to five operations that previously would have needed to be done on up to five different machines making it ideal for its primary purpose, which is to produce blanks for fringe items.”

Another new machine that has been purchased and installed in the carbide department is an ANCA MX 7 Linear, a versatile CNC tool grinder designed for production grinding

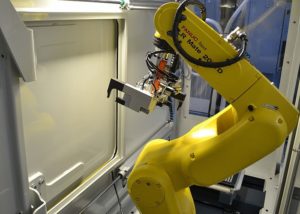

The ANCA MX 7 Linear versatile CNC tool grinder has been equipped with a Fanuc LR Mate 200iD robot that acts as a feeder for the machine and allows for seamless transition from raw stock to finished component without human interference

“Another new machine is the ANCA MX 7 Linear, a versatile CNC tool grinder designed for production grinding. This machine has been installed in the carbide department. The powerful 38kW permanent magnet spindle provides high torque at lower RPM, which is ideal for carbide grinding and a wide range of other applications. The ANCA MX 7 Linear machine is also equipped with the latest cylindrical linear-motor technology.”

“As we join the so called Fourth Industrial Revolution and we move towards digital manufacturing and unmanned production it is important that you invest in the latest technology to improve quality and drive down costs. Producing good parts with less labour is one way to drive down costs. But that’s especially difficult when tolerances get down into the microns and the parts require a 5-axis grind in carbide. Two things work together to achieve this. In-machine measurements to make sure you’re producing quality components and machine monitoring to collect and archive those measurement results to track machine performance.”

“And secondly you automate. On the ANCA MX 7 Linear we have included a new Fanuc LR Mate 200iD robot that acts as a feeder for the machine and allows us to seamlessly transition from raw stock to finished component without human interference.”

“This is not a new development for us. We have previously implemented unmanned production by installing a robot with a machine. We are investigating more options of where we can make more use of robotic handling without any concern that the products may be defective.”

Quality and inspection

“We make some of the most geometrically complex products out of the toughest materials and with the tightest tolerances. And yet cutting tools represent only 3% of the total cost of the average metalworking process. But you still have to maintain the tight tolerances.”

“This is the reason why we continue to invest heavily in our quality and inspection departments. Recently arrived in the tap department is another of what we call a floating carriage. The measuring machine joins five other floating carriages in this department.”

In the carbide department Somta have installed a Zoller Smart Check 420, a 3-axis CNC universal measuring machine that is designed to measure cutting tools, enabling efficient checking before and after the sharpening process to ensure absolute precision and documented results

The HSS department has been equipped with a new Zoller Genius 3, a measurement machine that fully automates the measurement of tools for in-process and final inspection

“The floating carriage is an ideal measuring machine for comparative measurement of the external diameter of any cylindrical threaded component having defined centres. This simple machine is the most reliable measuring equipment for measurement of effective diameter and major and minor diameters.”

“The HSS department has been equipped with a new Zoller Genius 3, a measurement machine that fully automates the measurement of tools for in-process and final inspection. The Genius is the universal measuring machine for cutting tools. From testing of individual criteria to complete, fully automatic and operator-independent checks, your workpieces are inspected quickly, simply and with maximum precision. The measurement results are documented in detail and transferred to our grinding machines at the click of a button. The Genius saves valuable time during planning, programming and production while ensuring optimum performance and quality first-time results.”

“In the carbide department we have installed a Zoller Smart Check 420. This 3-axis CNC version is a powerful universal measuring machine and is designed for all cutting tools, enabling efficient checking before and after the sharpening process to ensure absolute precision and documented results. It features swivelling incident light image processing software, which allows you to inspect, measure and record axial or radial geometries of tools at the click of a mouse button and without expert-level knowledge. Measurements can be transferred directly onto CNC grinding machines for more accurate machining.”

“Additionally our Goniometer has been upgraded to include cameras and digital readout for in-line measurement of tools and solid-state controllers have been installed in the heat treatment furnaces to replace the manual contactors. This saves on costs and reduces power usage, a more environmentally friendly solution.”

Further investment

“Somta continues with its exciting new journey as part of the OSG Group, and these investments are part of several new projects planned. A TGT Accudress wheel truing and profiling machine complete with a camera system arrives shortly. This machine will be utilised in the HSS factory as will the two 5-axis TGT V2 Advance Maxima CNC tool and cutter grinders that will arrive at the same time as the TGT Accudress. All three machines will be manufacturing HSS tooling.”

“We have also purchased microscopic equipment, including software, that is currently being installed in the heat treatment laboratory. This will take our analysis of HSS and carbide materials to another level.”

Recently installed in the tap department is another floating carriage. The floating carriage is an ideal measuring machine for comparative measurement of the external diameter of any cylindrical threaded component having defined centres

“As demand for coated products increases, Somta is also planning the installation of a second coating plant together with further engineering solutions to continually improve its manufacturing processes, guaranteeing a superior and precise range of cutting tools. The company, in line with OSG’s philosophy of improving local manufacturing, plans to pass the benefits of these future investments on to the market as soon as they are realised,” concluded Conolly.

For further details contact Somta Tools on TEL: 011 390 8700 or visit www.somta.co.za