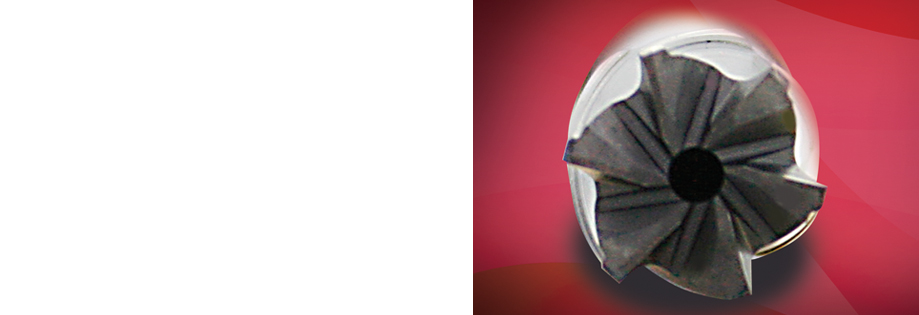

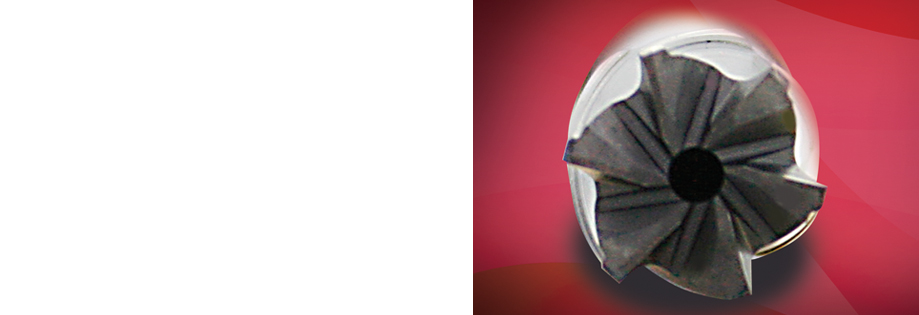

MTS Chipbreaker Drills

This outstanding development increases drill cutting efficiency by means of greatly improved chip control. A chipbreaker rib is positioned along the length of the flutes, which curls and breaks long chip forming material into small manageable chips for easier evacuation.

Colour Band Range

The need for greater productivity from expensive high-performance machine tools and the demand for the cutting tools to perform at optimum efficiency to minimize machine down-time, together with the demands for improved quality of machined components can be met with this range of Colour Band cutting tools.

SOLID CARBIDE HARD MATERIAL END MILLS

A range of high performance finishing end mills for operation on hard materials up to 52HRC (512HB), plus Somta’s hi-feed end mill with patent-pending geometry that removes the most amount of material in the least amount of time combined with extended tool life, for use on hard and super hard steels up to 65HRC (880HV).

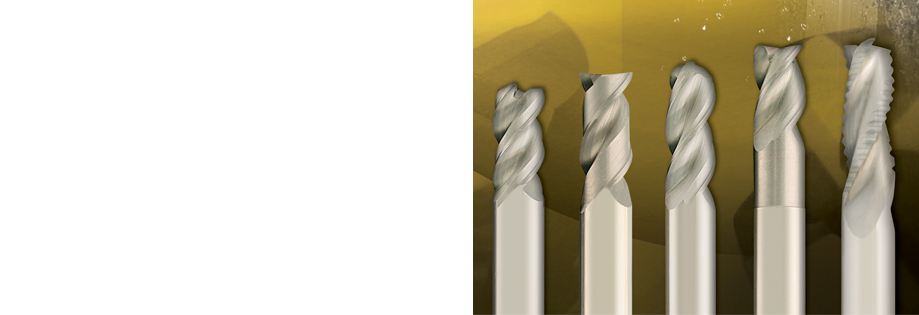

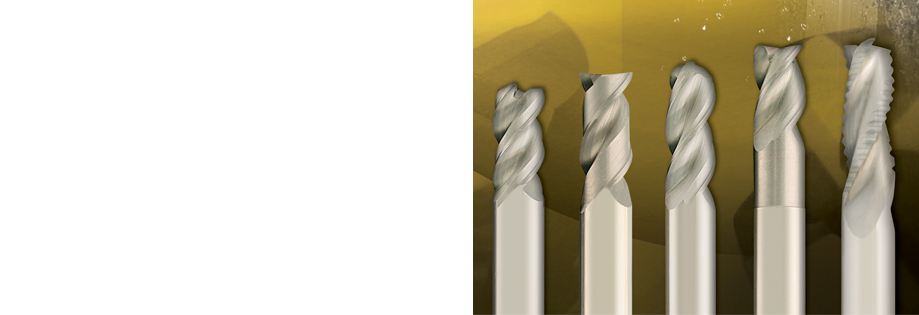

SOLID CARBIDE END MILLS FOR ALUMINIUM

Somta's high efficiency carbide end mill range with optimal flute geometry provides all the required features for high performance machining of aluminium, with the added benefits of greater stock removal rates at high speeds and feeds, excellent surface finish quality and extended tool life.

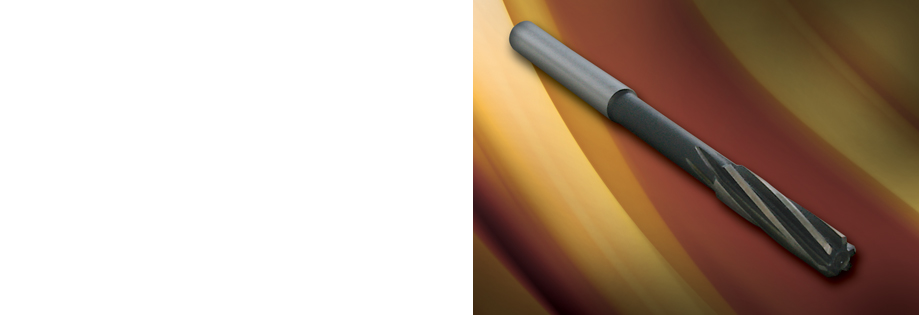

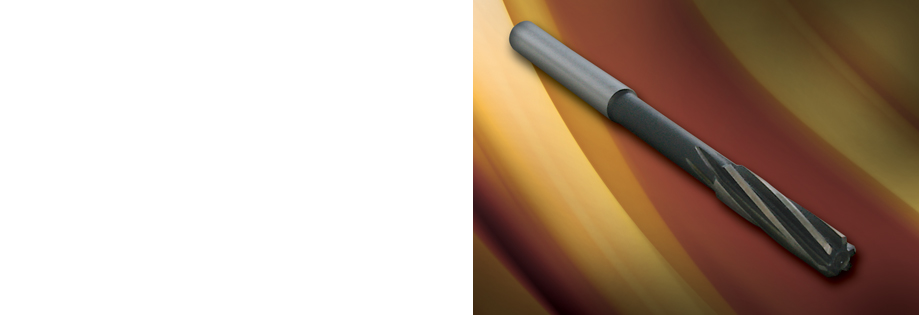

Reamer

Tool

Range

From closest tolerance precision machining of extremely accurate holes through to enlargement, alignment and deburring of holes for construction, assembly and general purpose applications. We have a product or a solution to satisfy your specific engineering requirements.

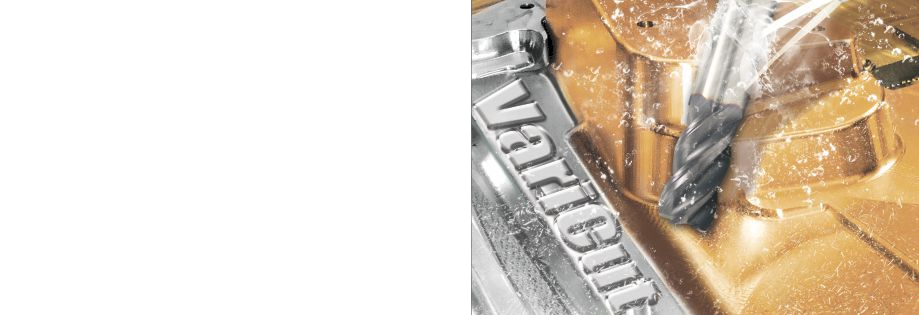

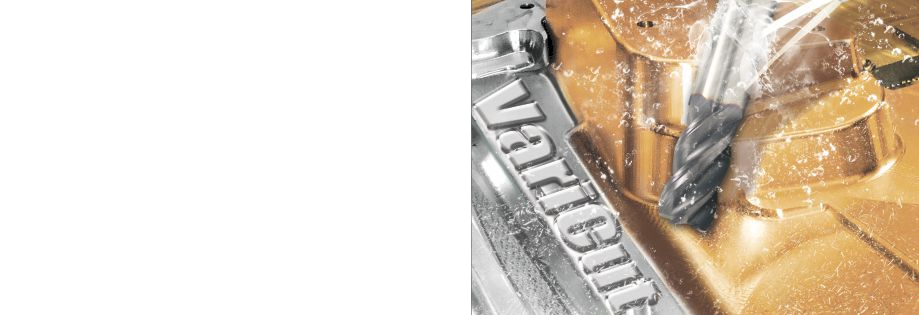

Solid Carbide VariCut End Mills

Somta's new “Vari-Style” End Mill, VariCut has a new patent pending tool design. This unique design uses a new core form and a new reinforced end geometry with unequal flute spacing which enables it to remove the most amount of material in the least amount of time with an excellent surface finish.

UD Ultra Parabolic Twist Drill

A comprehensive range of heavy-duty drills designed with improved point and flute geometries for enhanced penetration and chip removal in long chip forming, short chip forming and abrasive material groups. This range of drills is specifically designed to meet the challenges of a broad spectrum of difficult drilling applications.